Jean Goussard, Solutions Specialist

Statistics show that since the onset of the Covid-19 pandemic, many sectors and industries have expedited their digitalisation strategies to stay relevant and in business. The pandemic’s impact on the world economy and the restrictions it enforced on day-to-day business activities have pushed enterprises to embrace alternative methods to conduct their business, one being the introduction or integration of new or more digital technologies.

After almost two years of larger-than-life buzz acronyms such as ‘4IR’ and ‘IoT’, businesses increasingly see the need to start or continue investing in practical and scalable digital solutions for their operations. Businesses aim to optimise and gain some competitive advantage in ever-competitive and challenging markets and keep their doors open during the resulting global recession.

This article covers some practical examples of using digital technology, especially in the space of enterprise asset management that Pragma developed as part of our offering to our clients and their businesses’ success. It also gives some recommendations for organisations wanting to embark on their own digital transformation journey.

Adapting from paper to digital

The first example relates to quickly adapting and digitising a paper-based procedure. South Africa’s mandatory Covid-19 regulations placed severe strain on companies (including their employed workforce, contractors, service providers, and clients) to daily log and report Covid-19 related statistics. Understanding the high risk of transmission posed by shared paper forms, which most companies used to capture Covid-19 related symptoms, the Pragma team enhanced their native HSSE app with Covid-19 symptom tracking and reporting features. The HSSE app, with the primary function of logging potential and actual business and home-related safety events, became the central platform for health and safety logging in Pragma. The addition of Covid-19 specific reports simplified the tracking and trending of Covid-19 symptom and infection statistics and sped up organisational health and safety (OHS) reporting and compliance. The automated process significantly reduced the OHS team’s time, and the interactive dashboards provided additional insight into hotspots and high-risk areas for management to address business continuity risks. For users, the convenience of using the web-based app on personal smartphones created a sense of safety, and it increased efficiency by eliminating queues. Although digitising the process could be seen as a simple solution, it has had a significant impact on the organisation’s HSSE culture to comply with legislation, save lives and make the workplace safer.

Automation through apps

The second example involves using apps to automate service and work order requests and work order execution. A service or work order request is logged to report non-conformance and initiate the process of corrective work. Traditionally, a machine operator detects a fault in a production line. The operator notifies the line technician, either verbally, telephonically, or via email or message. The line technician raises a paper-based work request, completes the work, and adds feedback on the job card. The job card is sent to an administrator for capturing, after which reports are created from the captured data.

By digitising the traditional process, an organisation can gain significantly more value. The operator can directly raise a digital work request on a service request app, speeding up the process by excluding multiple people and mitigating the risk of communication errors between people. The operator selects the appropriate asset and views any open work requests against that asset. If another operator has already logged the fault, the operator knows to abandon the request. If not, a new work request can be logged, adding a detailed description and photo (if applicable), and prioritising the work with an urgency rating. Once in the system, the work order can’t get lost, and progress notifications keep the operator updated on the process. On management’s side, the scope of maintenance-related issues is visible, and they are in a much better position to prioritise and plan work based on importance. By enabling the operator and everyone within the organisation to raise work requests effortlessly, a much greater sense of asset management ownership is created to support organisational goals like improved and sustainable reliability.

A digital approach speeds up data collection and processing, giving organisations the business edge to timeously attend to organisational issues before they become crises. It also enables limited resources to focus on meaningful, focused improvement projects to stay competitive and sustainably grow the business.

The wonders of the digital twin

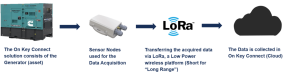

The third (and by far the most exciting) example involves the use of sensors and condition monitoring technologies to create a digital twin and give critical assets a voice. These so-called intelligent assets can inform operations of their health and performance status in real time, providing them with the data to predict potential failures and make timely and informed decisions. With much better control in place, organisations enjoy increased peace of mind.

A relevant example of this is emergency back-up generators that are required to keep businesses operational during power outages. In the South African context, the economy suffered the loss of billions of rands because of the crippling effect of load-shedding on business operations. An unstable and unreliable power supply can be detrimental to most businesses, causing a drop in manufacturing hours and service delivery and a loss of products or sales. So, the upkeep and reliability of our generators are critical.

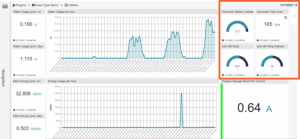

At Pragma, we replaced physical inspections to monitor the condition of our generators with remote online inspections. We combined different technologies and strategically placed sensor nodes to monitor the following critical areas:

- Generator Battery Voltage

- Generator Fuel Level

- Generator DB External Temp

- Generator DB Internal Temp

Pragma developed a custom dashboard with specific graphs and dials to reflect the real-time data visually. An early warning system was developed with specific parameters, levels and triggers to notify the relevant person (Pragma’s facilities manager) via SMS, email or automated work order. For example, if the fuel level drops below a certain point (eg 100 litres) an automated work order is generated via the enterprise asset management system (EAMS). An interface between the cloud and the EAMS eliminates the need for a person to walk around and manually capture the information daily. The frequency of the information gathered can easily be adjusted from twice a day to hourly if needed.

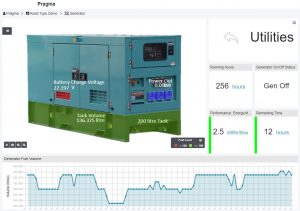

As part of the visual platform, a digital twin can also be created, displaying the asset with all the sensor nodes and critical measuring points as per the below transformer example.

Doing digital transformation, the right way

We suggest that before an organisation embarks on a digital transformation journey, a Digital Transformation Strategy must be developed to understand the requirements and objectives of the organisation. It is very easy to get disrupted by technology and go down a costly rabbit hole.

First ask whether it makes sense to measure an asset with these key questions:

Does it add value?

Is it cost-effective?

Will it provide a competitive edge or just drive efficiency?

Do I have the necessary support in place for the upkeep of the interface?

Is it in line with the company’s Digital Transformation Strategy?

Things to consider when designing your Digital Transformation Strategy:

We urge organisations to consider the following recommendations before embarking on this journey:

- Understand the organisation’s requirements

- Maintain alignment with all key players

- Ensure sufficient value will be gained

- Select mature, easily maintainable and agnostic technology

- Consider device management flexibility

- Be aware that continuous monitoring might not always be the solution

- Implement a flexible and interoperable IoT solution – plug ‘n’ play

- Integrate into existing systems if available (Can the new solution be retrofitted?)

To conclude, IoT automated processes are here to stay but should be approached with caution and not because IoT or 4IR is the latest trend or buzz word. Measurement or monitoring should not be done for the sake of measuring. Organisations should start with an Asset Management Policy and Strategy and align any Digital Transformation to it.